The daily functions we sometimes overlook—like water management, power generation, and manufacturing—depend heavily on automation. At the heart of this automation lies the Supervisory Control and Data Acquisition system, also known as SCADA.

When dealing with SCADA systems, the stakes are high. Beyond just controlling equipment, SCADA systems can be guardians of public safety and stewards of valuable resources. For utilities like the water and wastewater field, modern systems help protect the public. They reduce human error and ensure reliable water services. These systems also prevent spills and avoid contamination events.

When a strong system uses digital transformation tools well, it can be a source of value and performance. This is especially true when it works with skilled and experienced operators. Although a well-maintained system requires continual investment, the payoff becomes evident through the ease of staff operations and the reductions in costs for treating and delivering water.

SCADA is frequently used interchangeably with “industrial control system.” However, it is actually a subsystem that manages data collection and the presentation of graphical interfaces. SCADA used to mean just screens and data. Now, it includes networking equipment and programmable logic controllers (PLCs).

As a system of software and hardware elements, SCADA allows industrial organizations to:

SCADA typically consists of seven components:

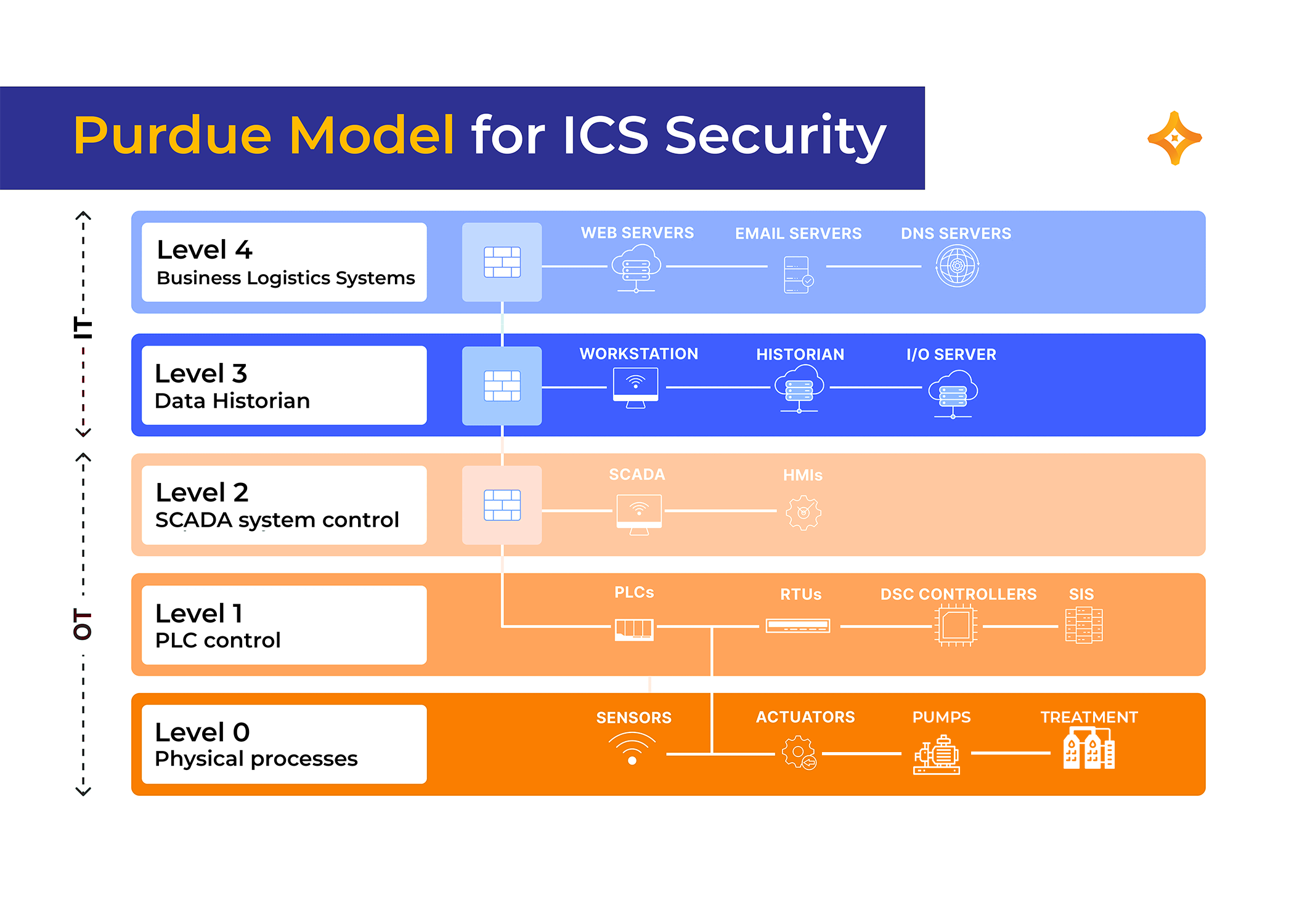

Dividing SCADA networks into specific functional zones is essential for boosting cybersecurity and the efficiency of industrial control systems. This organized method minimizes the attack surface, enhances data flow management, and optimizes system performance by arranging the system into separate layers. In adherence to the Purdue Enterprise Reference Architecture, this is how we recommend segmenting your network:

Virtualization has emerged as a crucial technology in contemporary systems, allowing organizations to manage control systems with greater efficiency. By simulating physical hardware, multiple virtual machines (VMs) can run on a single physical server, resulting in improved efficiency, scalability, and cost savings. Traditionally, SCADA systems depended on dedicated physical hardware, which presented challenges like limited capacity, high maintenance expenses, and complicated redundancy configurations. Virtualization resolves these problems by separating SCADA software from the hardware, enabling dynamic resource allocation and more effective use of infrastructure.

The key benefits of virtualization include:

Virtualization enhances SCADA system efficiency, providing cost reductions, increased adaptability, and enhanced disaster recovery, while promoting collaboration between IT and operations teams.

To develop an effective SCADA system, organizations optimize long-term value by following a structured process: