Fresno Cogen Upgrade

Wellhead Power Solutions

Customer Background

Wellhead Power Solutions (WPS) is a privately held developer and operator of innovative energy generation and energy storage facilities across California. These facilities produce over 400MW, and their operations continue to expand.

Enterprise Automation was brought on board in early 2022 to provide an extension of staff planning and implementation capabilities as part of an initial 2-year contract.

Project Background

With any industrial facility and accompanying SCADA system, modernization and system updates are a constant requirement. WPS identified the need to replace the SCADA and control system at their Fresno plant as part of ongoing upgrades. Their internal engineering team had developed software templates and hardware standards to streamline their systems with the latest technology. While the templates and standards were well established at several WPS facilities, they had not yet been introduced to every plant.

The WPS engineering team was implementing process changes at the Fresno plant, which meant the opportunity for plant downtime would allow the control upgrades to take place at the same time. To ensure the limited downtime was enough to take care of the conversion, Wellhead decided to augment their staff with members of the EA team. EA was a great fit because of their extensive knowledge of SCADA and PLC systems, software migration, and hardware compatibility. As an AVEVA Plant SCADA (formerly Citect) user, Wellhead preferred a partner with additional product depth. EA has hundreds of past projects involving Plant SCADA and was more than comfortable with the assignment.

EA Solutions

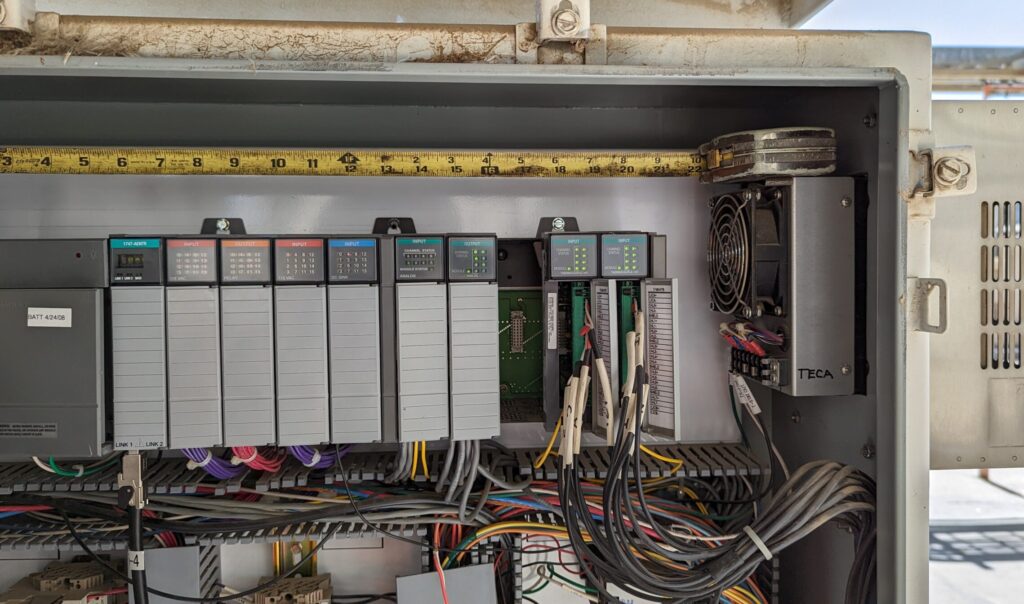

Conversion projects present a high level of risk due to the functionality and communications that must be maintained during the process. With nothing to fall back on, there is a heavy emphasis on getting the installation right the first time. EA met this challenge by identifying, testing, and resolving several issues upfront, including panel sizing and conversion module compatibility. Identifying these potential roadblocks early in the process allowed for proper project planning to meet the tight deadline and outlined key areas to validate in the office before arriving for the startup in the field.

The primary focus of the project was completing hardware upgrades and converting the existing code. New ControlLogix and CompactLogix PLCs replaced the existing PLC-5s and SLC-500s. The remote IO racks were upgraded to new ControlLogix backplanes and connected to the new PLCs. Conversion kits were used with the IO module replacements since most of the existing wires were in good shape, adding adapters to connect to the new hardware. The software files underwent complex program conversions. With EA’s background knowledge, engineers efficiently worked through and tested the code ahead of the installation.

After successfully installing the new hardware and software during the planned downtime window, EA stayed onsite to support WPS during the plant startup procedure. In addition to reviewing the changes and basic troubleshooting steps with the operators, EA also worked with the internal engineering team to validate their new Citect SCADA platform. EA assisted with the HMI verification, including screen linking to statuses in the field.

The project was completed within the tight downtime schedule thanks to WPS and EA’s due diligence and risk mitigation. EA’s open communication throughout the project supported the overall success and paved the way for future projects with WPS.

Key Insights

- EA supported the internal engineering team with hardware verification, software conversion, installation validation, and onsite support.

- Properly identifying hardware compatibility issues early on mitigated many project risks during the software conversion.

- IO module conversion kits were used to reduce installation time and connect existing wires to the new hardware.

Key Technology

- Allen Bradley CompactLogix

- Allen Bradley ControlLogix

- AVEVA Plant SCADA (Citect SCADA)

Project Metrics

- Project Length: 4 months